Systembiotechnologie

Systems Biotechnology Group

The transition to a green and sustainable chemical industry necessarily involves exploiting the metabolic capabilities of microorganisms. Bioprocesses with microbes offer a clean alternative to established chemical processes, with low temperatures and energy requirements, and basically no chemical waste. Metabolism, the network responsible for generating both the energy and molecules living cells need for growth and ecological fitness, is a fascinating machinery. It is at the same time robust and malleable, thus rendering it highly adaptive to meet many different demands.

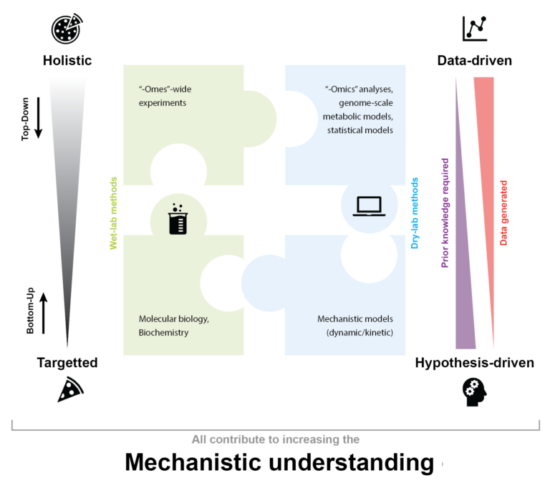

We study and engineer metabolism for the development of industrial biotechnological solutions that replace current fossil based industries. We rely on mathematical modelling to understand, quantify, and modify the highly complex interactions inherent of metabolic networks. We also analyse the behaviour of living organisms at a cellular level to optimize the scaling up of bioprocess, with particular emphasis on the use of different feedstocks and dynamic culture conditions.

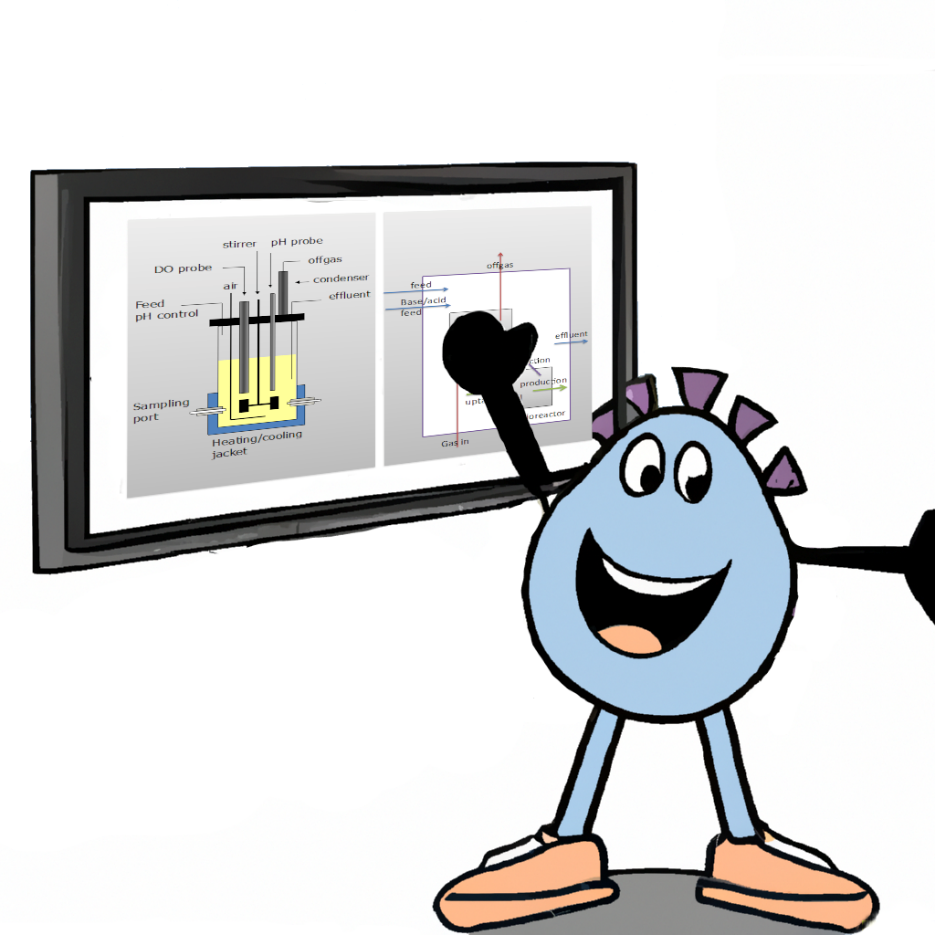

Our research group offers broad expertise with metabolic network modelling approaches, including quantitative fluxomics under dynamic conditions using 13C tracing [1, 2], integration of cellular resources like proteome space in dynamic flux predictions [3, 4], and the integration of thermodynamic constraints [5]. Our experimental capabilities include bioreactor cultivation in the scale of 0.5-15 liters under dynamic conditions and defined feeding profiles. The setups allow for rapid sampling coupled with high-resolution mass spectrometry to generate large metabolomic and proteomic datasets.

Currently, we use this methodology to tackle feedstock dynamics & interactions under co-substrate conditions. The next generation of feedstocks will consist of a combination of C-sources from agricultural waste (2nd generation feedstock) and sources derived of the electrochemical reduction of CO2, such as methane or methanol. Using metabolic models to understand the interactions between different assimilation pathways , as well as studying the metabolic and proteomic behaviour and responses of the cell under different static or dynamic feeding profiles, will allow us to engineer microorganisms capable of using mixtures of complementary sustainable feedstocks, therefore enabling fully renewable based production of chemicals.

Teaching:

The group’s teaching activity is embedded in curriculum of the Life Science and Engineering (LSE) at the FAU Erlangen-Nürnberg. Students dive into the exciting world of metabolic networks, engineering and modelling of metabolism, and learn about the newest approaches in Systems Biology. All lectures are complemented with computer-based exercises and practical courses in which the students directly apply the methods learnt. Courses include:

– Metabolic Engineering, 5 ECTS in the LSE bachelor program.

– Systems Biotechnology, 7.5 ECTS in the LSE master program

– Parts of Bioanalytics, 5 ECTS in the LSE bachelor program

Furthermore, we are active in the design and teaching of post-master education courses:

– Integrated Multi-Omics approaches for Improvement of Industrial Microbes at TU Delft

References:

- Suarez-Mendez CA, Hanemaaijer M, ten Pierick A, Wolters JC, Heijnen JJ, Wahl SA: Interaction of storage carbohydrates and other cyclic fluxes with central metabolism: A quantitative approach by non-stationary <sup>13</sup>C metabolic flux analysis. Metabolic Engineering Communications 2016, 3.

- Verhagen KJ, van Gulik WM, Wahl SA: Dynamics in redox metabolism, from stoichiometry towards kinetics. Current Opinion in Biotechnology 2020, 64.

- Verhagen KJA, Eerden SA, Sikkema BJ, Wahl SA: Predicting Metabolic Adaptation Under Dynamic Substrate Conditions Using a Resource-Dependent Kinetic Model: A Case Study Using Saccharomyces cerevisiae. Frontiers in Molecular Biosciences 2022, 9.

- Paez-Watson T, van Loosdrecht MCM, Wahl SA: Predicting the impact of temperature on metabolic fluxes using resource allocation modelling: Application to polyphosphate accumulating organisms. Water Res 2023, 228:119365.

- Cueto-Rojas HF, van Maris AJA, Wahl SA, Heijnen JJ: Thermodynamics-based design of microbial cell factories for anaerobic product formation. Trends in Biotechnology 2015, 33.